Get to Know Hamamatsu

- Eat

Liquor x Chocolate Jenne’s fascinating trip to Hamakita! ②

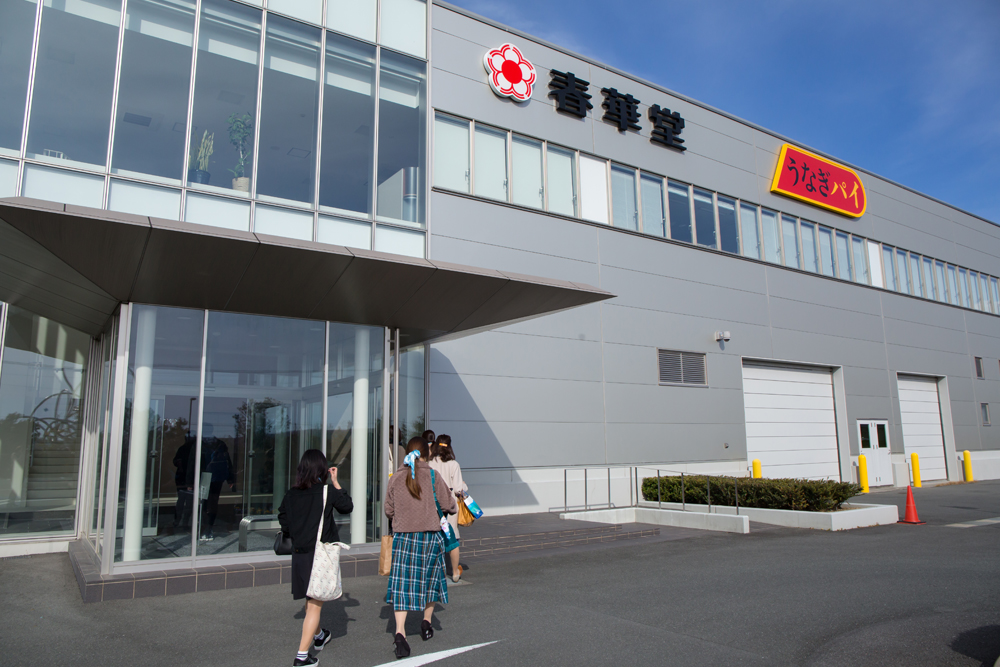

Next, Jenne and her friends came to Nicoe, which is also located in Hamakita. This facility opened in July 2014 and is operated by Shunkado, famous for its eel pie. Based on the concept of “Hamakita Sweets Community, transmitting a new culture and style of sweets,” it is a facility that everyone from children to adults can enjoy. Of course, they also sell eel pies, and you can purchase most of the sweets made by Shunkado. That’s not all. There is also a different blend called Gokokuya, and there are also sweets that can only be purchased at Nicoe in Hamamatsu City.

Chocolate bar making experience at “cacao lab.”

Well, today’s purpose for Jenne and her friends is to experience making chocolate bars at “cacao lab.” With Valentine’s Day approaching, it’s a perfect experience for this time of year. Many women may have made sweets using chocolate. However, this time, we will be making chocolate from cacao beans. Apparently, this process is called “Bean to Bar.” Looking forward to an unknown experience, I headed to the Shunkado Hamakita factory located on the north side of Nicoe’s facility. The cacao lab is located in a building that houses offices and a staff cafeteria.

After being guided to the facility, I immediately washed my hands and put on an apron. First, a researcher wearing a white coat will give a lecture on the entire process from cacao beans to making chocolate. There are five steps, so it didn’t seem that difficult. First, start by peeling the shells of the cacao beans. Do you know about cacao fruit? These days, you often see them on the packaging of commercially available chocolates. I was surprised when I saw the actual size model. It’s like a rugby ball. This contains cacao beans. I ate one while I was working on peeling beans. Jenne tilts her head. The aroma is chocolate, but the beans themselves have the impression that they contain oil and have no taste. Even though they are the same bean, they taste very different from soybeans.

You must peel the shell to the specified amount. Jenne and the others immediately concentrate in silence. The peeled cocoa beans are placed in a mill and ground. Somehow, we finished measuring and began the process of conching. Normally, this conching process takes an enormous amount of time. This step is essential for making chocolate with a smooth texture. In order to achieve a smooth texture in a short amount of time, ground cacao beans, sugar, and cacao butter are placed in this special conching machine according to the measured amounts. When you press the switch, the chocolate is mixed with butter and the chocolate liquid is completed. It already looks delicious.

Next, we begin the process of tempering. Tempering is an indispensable process for making beautiful, glossy chocolate by adjusting the temperature of chocolate. Pour the chocolate liquid from earlier into a bowl, cool the bottom with water, and mix. Then add hot water to bring it to the appropriate temperature. The students divided into groups and performed this task while measuring the temperature. This is strange because it doesn’t reach the right temperature. I think I understand why delicious chocolate is expensive. This is probably because it is made through such a time-consuming process.

Once it reaches the appropriate temperature, pour it into the mold. It seems that whether or not the tempering was successful depends on how solid the chocolate is during this process. Hurry and add the toppings of your choice before it hardens. The chocolate bars become colorful and unique, including pink raspberry and green pistachio. I’m looking forward to seeing it completed. Let it sit in the fridge for a while to firm up for the final finishing touches. In the meantime, draw a picture on the label. Another silent moment came. Concentrate and draw different pictures each time. Her personality is shown here as well, and it becomes fun for people to watch.

Remove the hardened chocolate bar from the mold and taste it first. delicious~! Jenne and her friends are satisfied with the taste of the chocolate they made themselves. I will package the rest. Just wrap the label from earlier and you’re done.

Jenne and her friends photograph the completed work with a camera. A truly adorable, one-of-a-kind chocolate bar has been born. it was fun~! I want to come again! One of the most satisfying aspects of this experience is that you can take home a chocolate bar.

Dinner at THE COURTYARD KITCHEN

After leaving cacao lab., we bought some souvenirs at nicoe! I’m not going home yet. You can also have dinner at THE COURTYARD KITCHEN. The charm of this place is that Michelin-starred chef Shinji Harada oversees the menu, which uses plenty of local ingredients, and that you can enjoy Shunkado’s signature sweets in buffet style. We enjoyed a sumptuous dinner while exchanging impressions about making chocolate bars.

Shunkado is a representative company in Hamamatsu. This company, which created the eel pie that everyone knows, will continue to create projects that everyone from children to adults can enjoy. A true Hamakita Sweets community. This is the place where you can find sweets that will make your heart smile.

For more information click here